Automation

Overview of MA Series CNC for automatic tube rolling

Check out below all the machines designed and produced by Maus Italia for the automation of the tooling operations necessary for the serial production of tube bundle heat exchangers.

Automatic CNC tube rolling work centre with machine vision and pallet change

MA-400

MAUS ITALIA has solved the problem of production of tube bundle batches with small dimension with an automatic tube rolling work centre complete with innovative solutions More than 600 tubes/hour - 1 cycle in less than 6 seconds

Fixed-based single-axis CNC work centre for serial production rolling and end facing tube bundle tubes

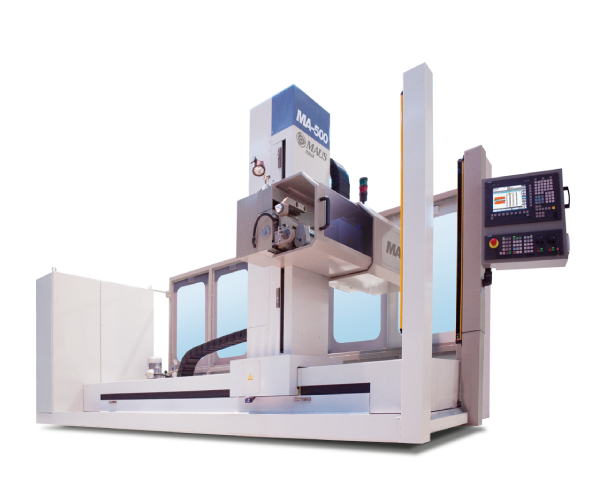

MA-500

The MA-500 is the most innovative and efficient of Maus Italia’s products for the automation of serial production assembly work cycles for small heat exchangers. Maximum tubesheet diameter. 1000 mm ( 40” )

CNC single- or double-axis work centre with mobile base for rolling, facing, grooving and TIG orbital welding of tube bundles

MA-2501

The MA-2501 is the most innovative and effective solution offered by Maus Italia for the automation of work cycles for the serial assembly of medium to large heat exchangers. Maximum tubesheet diameter. 2500 mm ( 100” )

CNC single- or double-axis work centre with mobile base for rolling, facing, grooving and TIG orbital welding of tube bundles

MA-3501

La MA-3501 is the most innovative and effective solution offered by Maus Italia for the automation of work cycles for the serial assembly of medium to large heat exchangers. Maximum tubesheet diameter. 3500 mm ( 140” )