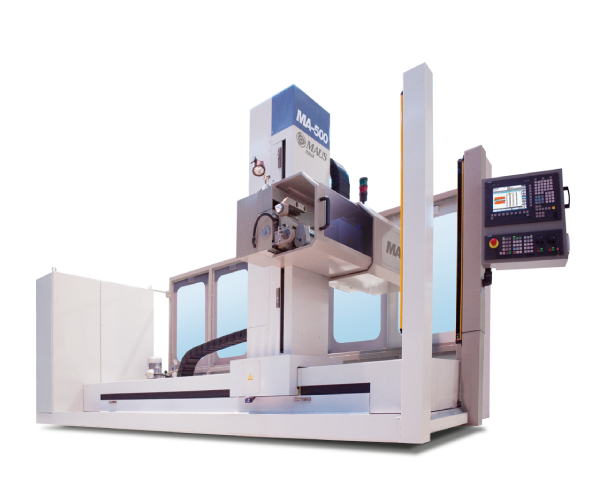

Baffletech twin 2000 - Automatic centre with double head for flaring holes in the heat exchanger baffle

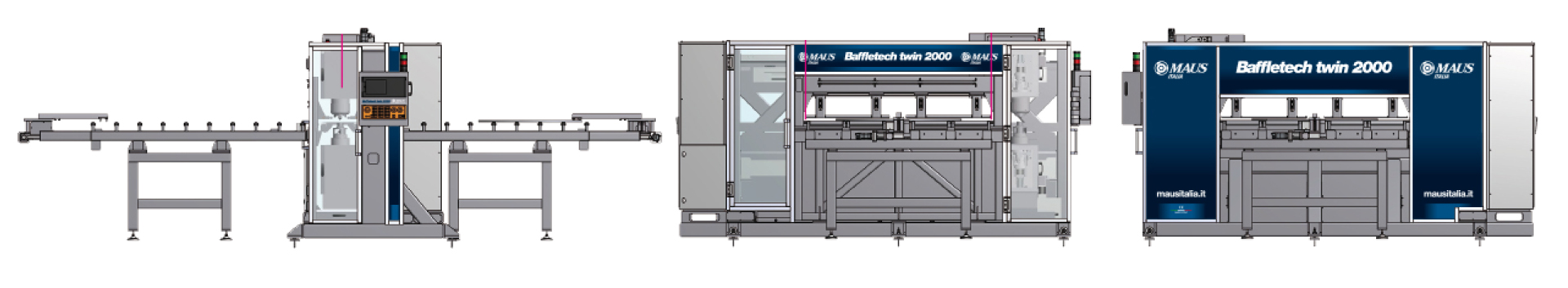

Baffletech twin 2000 - Automatic centre with double head for flaring holes in the heat exchanger baffle up to 2000 mm in Ø (78")

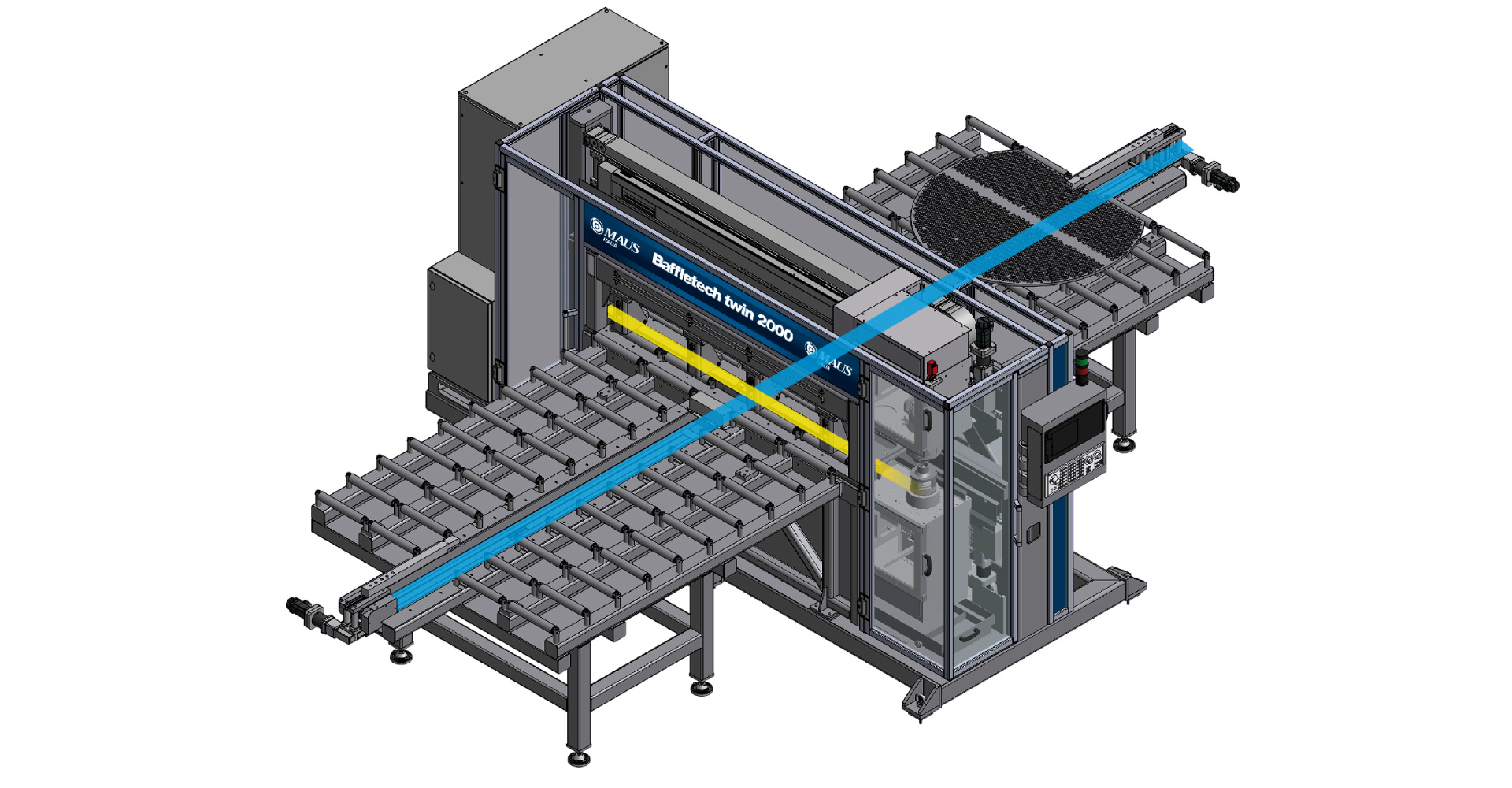

The Baffletech twin 2000, entirely designed and manufactured by Maus Italia, allows the simultaneous flare of the holes on both sides of the baffle in a single pass without the need of additional operations thanks to two opposing heads which are equipped with self-centring tools

Exclusive production features

Exclusive patent

Maus Italia

Up to 2000 holes per hour

Automation

Maximum productivity

Working production

CNC controlled

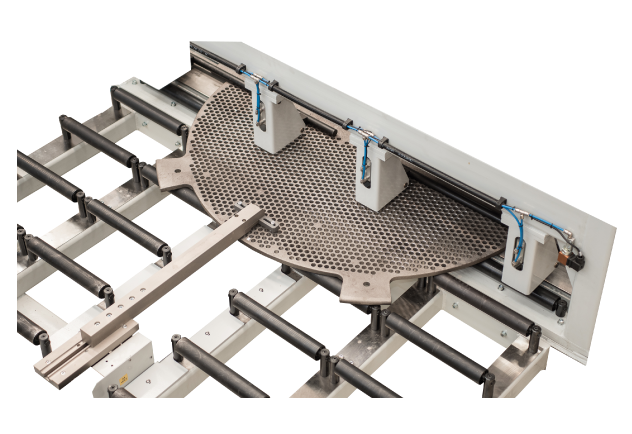

Automated process along roller tables

The baffle are loaded on one the side of the machine, proceeds along roller tables thanks to motored arms, which once the flaring phase is finish, will bring the baffle to the unloading position

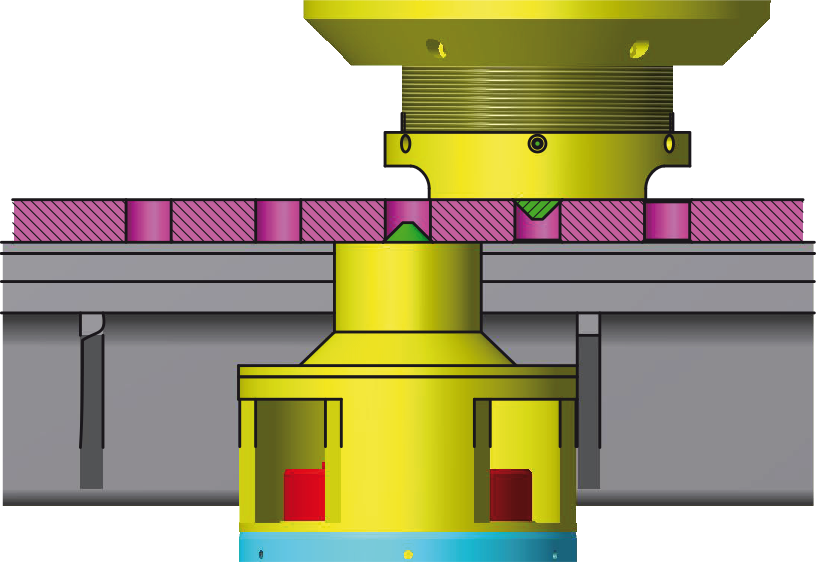

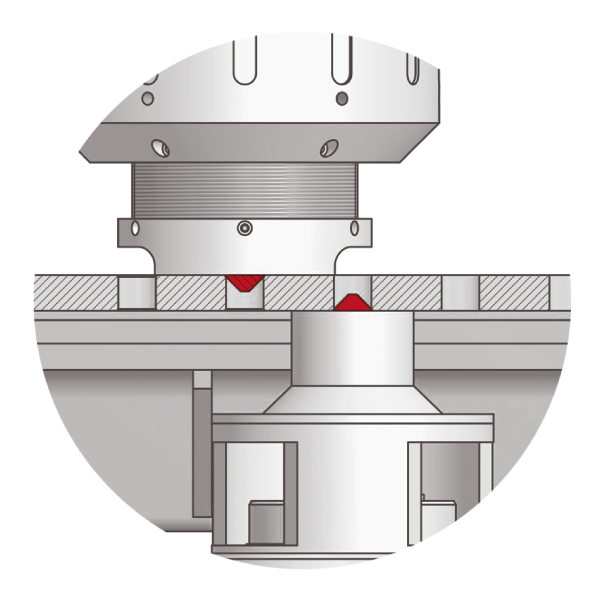

Flaring holes technology

The two thrust collar mounted on the opposing heads will position against the baffle while the two flaring tool will execute the flare according to the machine program.The flaring of the holes is perfectly centered and is always at the same depth thanks to the zero-set of the tool. The row of holes is rapidly machined on both sides with the transverse movement of the two independent heads.

Automation plus

The Baffletech twin 2000, is equipped with CNC control for:

High quality and exceptional working speed

Image gallery of Baffletech Twin 2000

Product technical datasheet

If you would like all the technical information related to this product, please download the .pdf brochureor get in contact with us directly, our qualified personnel will answer to your queries.