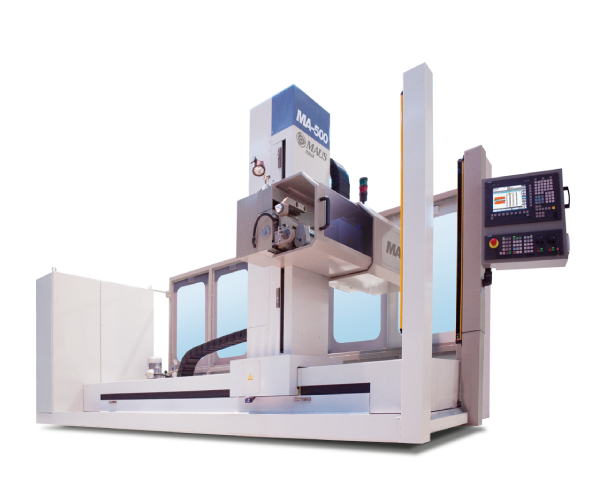

MA-400 - Automatic CNC tube rolling work centre with machine vision and pallet change

MA-400 Automatic work centre for rolling of tube bundle tubes

MAUS ITALIA has solved the problem of production of tube bundle batches with small dimension with an automatic tube rolling work centre complete with innovative solutions, such as:

The revolution is in the automation

Repeatability guaranteed

of the tube-tubesheet joint guaranteed

Productivity

unparalleled

High speed

More than 600 tubes/hour - 1 cycle in less than 6 seconds

Quality and uniformity

Tube rolling always certified

Automatic CNC tube rolling work centre with machine vision and pallet change

Quality, uniformity and repeatability of the tube-tubesheet joint guaranteed

Quality, uniformity and repeatability of the tube-tubesheet joint guaranteed

Unparalleled productivity

A series of measures and applied technologies allow the MA-400 to work at high speed with the achievement of more than 600 tube expansions per hour

Total automation

The MA-400 productive process does not require the continual presence of an operator who can then, as a result, dedicate his time to the preparation of the next pallet to avoid machine down times

Immediate programming directly from the tube sheet design

The software created by MAUS ITALIA, known as MausCAM, has evolved to aid the MA-400 as an interface for X-Y programming by reading the CAD drawing of the drilling pattern of the tube sheet

Self-learning machine vision centring system

The necessity of reducing production times has led the MAUS ITALIA technical staff to make use of a camera, thus avoiding any type of mechanical contact for the centring of the tubes.

Operational simplicity

The extremely user-friendly control console ensures access to all parameters by the operator

Tube rolling always certified

Each tube expansion with X-Y position, expansion and torque data is monitored in real time and the information collected constitutes the report for certifying the completed work

Operation with tube bundle batches pallet change

MausCAM

Interface software for X-Y programming

Created by MAUS ITALIA technical staff to facilitate the expansion of work cycles, it allows the automatic processing of a CAD design of the tubesheet hole pattern

DXF from standard CAD

The system is based on reading the DXF drawing interchange format and is able, in a few steps, to process the CAD file of the tube sheet and automatically obtain the matrix of the coordinates of the tubesheet holes.

Interactive processinga

During processing, you can check and optimise the path according to its position or geometry. If the tubesheet is larger than the available stroke, you can subdivide the tubesheet into multiple sectors that will be processed at different times.

FOCS 4 Sight

Self-learning centring system with camera

Machine vision system for the automatic centring of tubes without mechanical contact. Combines higher rapidity with extreme precision guaranteeing:

Immediate identification of the zero work piece;

Detection and automatic correction of any hole positioning errors;

Programmable intervention for each tube and at regular intervals;

CNC control console

User friendly

Located to ensure maximum visibility of the work zone, it is extremely user-friendly and ensures maximum operational simplicity and access to all parameters by the operator.

Real-time report for a tube expansion which is always certified

The constant and growing demand for documentation suitable for certifying the total quality of the jobs is satisfied by thorough and detailed data archiving.

The report file, as well as recording the dimensional measurement of the rolled tube, also saves its position on the matrix of tubesheet holes, ensuring total traceability of each operation without the possibility of error.

Maus Italia machinery will transform you into a Smart Factory!

The compliance of the MA-400 with the requirements of the "INDUSTRY 4.0" system has been examined by an accredited third party and has been deemed adequate to allow interconnection between the machine and company systems.

Image gallery of MA-400

Product technical datasheet

If you would like all the technical information related to this product, please download the .pdf brochureor get in contact with us directly, our qualified personnel will answer to your queries.