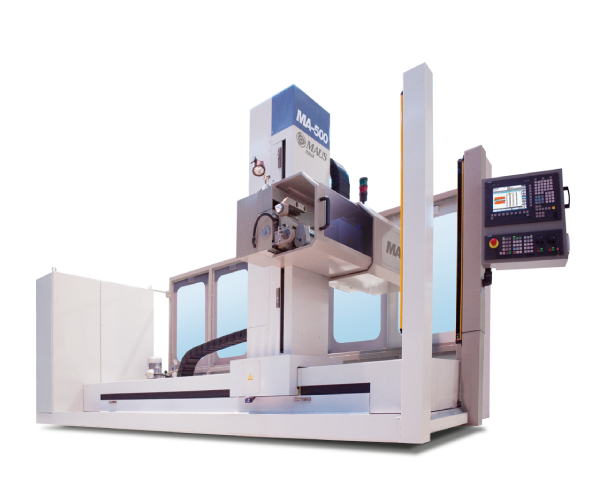

Automatic welding system MaTig-502

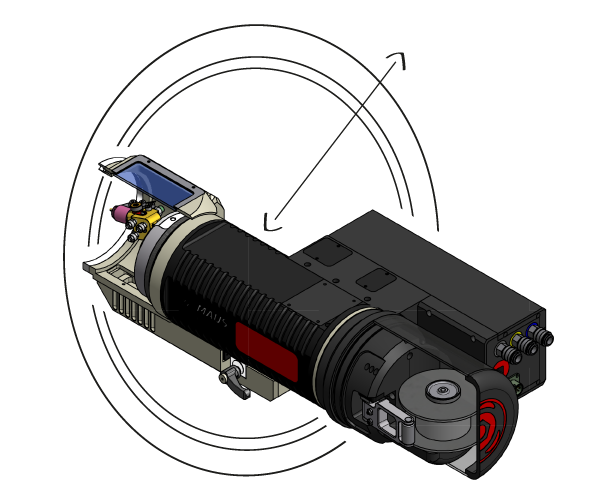

MaTig-502 Automatic positioning tube to tubesheet TIG orbital welding system

MAUS ITALIA presents the evolution of its TIG orbital welding work centre with new functional, ergonomic and aesthetic solutions, in response to practical requests from its increasingly demanding customer base.

With its Giotto 250 Auto welding head, graphic interface, MausCAM software and many other components of the highest quality, a milestone has been reached in the quality control of the tube-tubesheet welded joint.

From extraordinary to revolutionary in 4 key points

Fully automatic

The only machine in this sector which is completely autonomous and automatic.

Extreme cost reduction

Rapid positioning, ease of programming and optimisation of the welding cycle reduce production costs.

High speed

Digital management of the rotation parameters of the torch allows speeds of up to 10 revolutions per minute.

High precision

Welding geometries with an accuracy that has never been reached before.

NEW MaTIG 502 general features

Filler wire automation

Control of the flow, the end of the reel and the rotation of the spool on the orbital axis increases the repeatability of the weld.

Management of the welding arc

Continuous monitoring of the welding current ensures constant penetration across the whole weld.

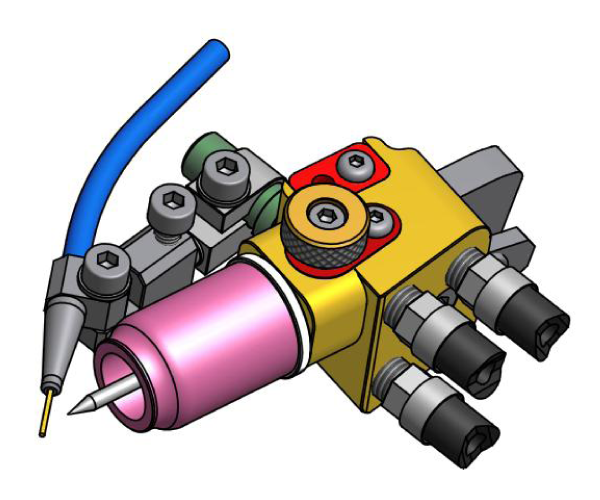

Laser centring probe

Unique centring system guarantees the highest precision in the geometries of the welded joints.

MausCAM - CAD/CAM software

Dedicated software for intuitive DXF programming for the construction of the tubesheet drilling coordinate matrix.

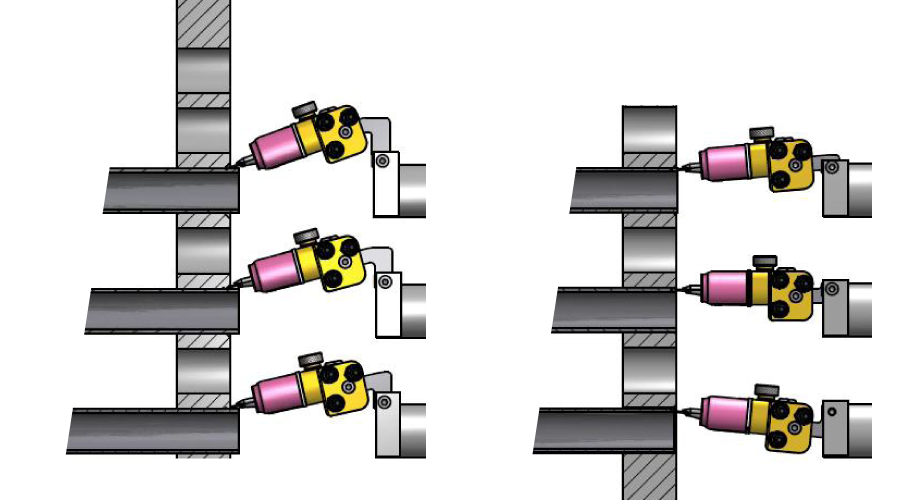

Electrode angle of incidence

Thanks to a set up with predetermined angles, repeatability of the weld is guaranteed over time.

INTERPOL 3 Variable radius AVC3D

In multi-pass welding, the radius is controlled and interpolated by CNC, reducing production times even further.

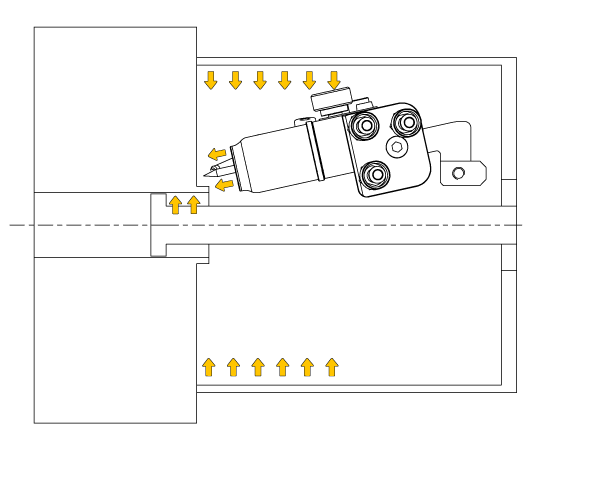

Protection of the tube

The integrated rotating purging system guarantees protection of the tube interior during welding.

Additional gas

Introduction of a third gas line and separate flow management on each line.

Enter the Industry 4.0 with MaTig-501

The CNC/PLC machine manufactured by Maus Italia perfectly follows the requirement of the "Internet of things" being equipped of systems that allows to obtain data and statistics indispensable for handling the internal process and to be able to take strategic decision for the company development. Contact us, we will be at your complete disposal for any information.Discover the new software that can transport your company in the Industry 4.0"

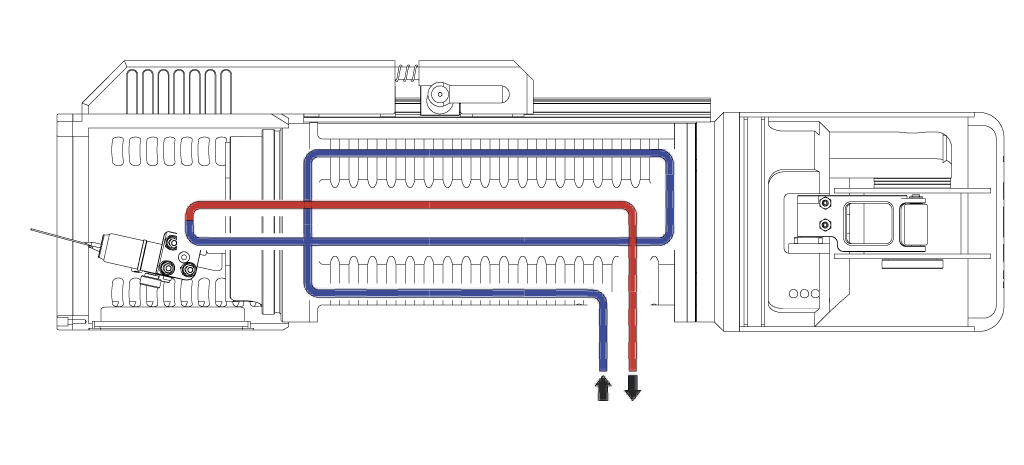

24/7 use Cooling system inside torch

Effective water cooling system inside the MaTIG 502 orbital welding head guarantees:

Laser centring probe FOCS2

Self-learning FOCS2 laser centring system which can work in sync with the CNC as well as independently. Unique self-learning electro-pneumatic centring system guaranteeing precision of the geometries of the welded joints managed by dedicated MAUS ITALIA software.

Protection of the tube "purging" system

The integrated rotating purging system guarantees under head protection of the tube during welding.

Electrode angle of incidence

Thanks to components with preset angles, the system setting is absolute and repeatable for all welding geometries.

Facilitates geometric set up operations as well as being extremely stable and robust.

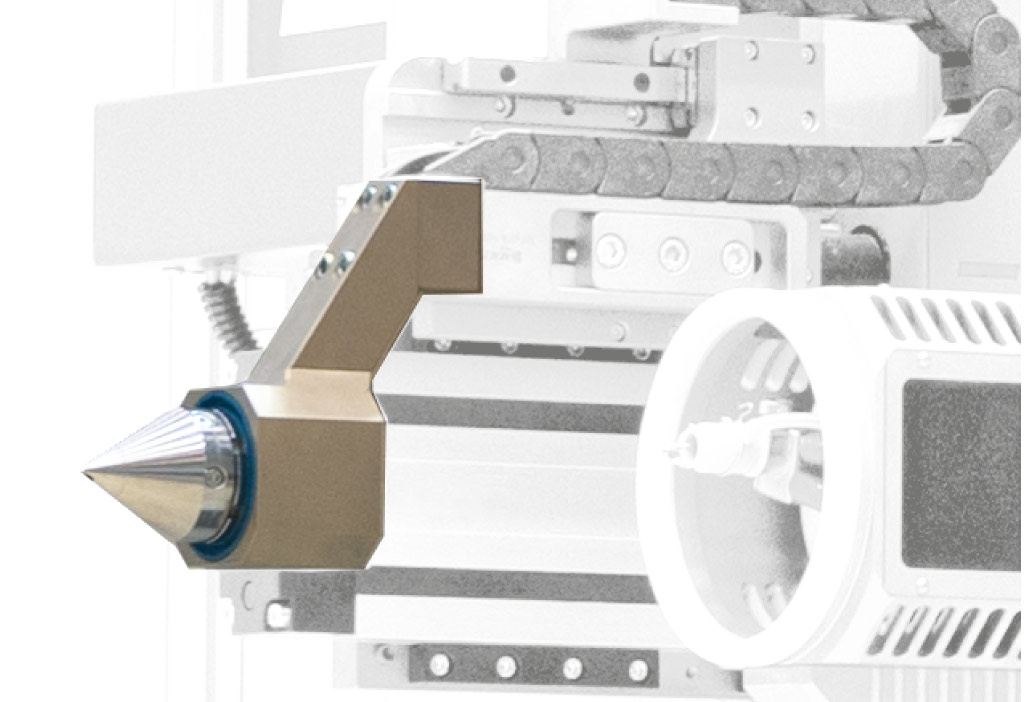

Unique TIG welding torch

The only product of its kind. The new orbital TIG welding torch has been designed and manufactured in its entirety by MAUS ITALIA. The new electrode clamping system with tangent screws does not require service keys and makes replacing the worn electrode quick (it is no longer necessary to dismantle the ceramic nozzle, the relevant gas diffusor and the filler wire guide).

The wire feed assembly is fully adjustable in all directions. All operations are carried out with a single supplied key.

Automation of the filler wire

INTERPOL3Variable digital radius

In multi-pass welding, the rotation radius of the electrode can be controlled and interpolated by the CNC

Quick changeQuick welding head alignment

New hardware solutions provide quick alignment of the welding head with the axes of the MaTIG502 in case of disassembly or replacement for maintenance, reducing downtime.

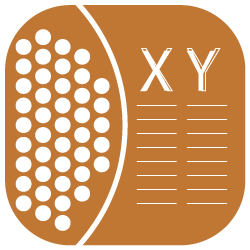

MausCAM

Conversion software for X-Y programming starting from CAD drawing used for tubesheet holes drilling

DXF from CAD standard

The system is based upon the reading of the DXF drawing interchange format and is able, in a few steps, to process the CAD files of the tube sheet and automatically obtain the matrix of the coordinates of the tubesheet holes.

Interactive processing

During processing it is possible to control and optimise the path according to the position or the geometry. If the tube sheet is larger than the usable stroke, it is possible to divide the program into several successive parts.

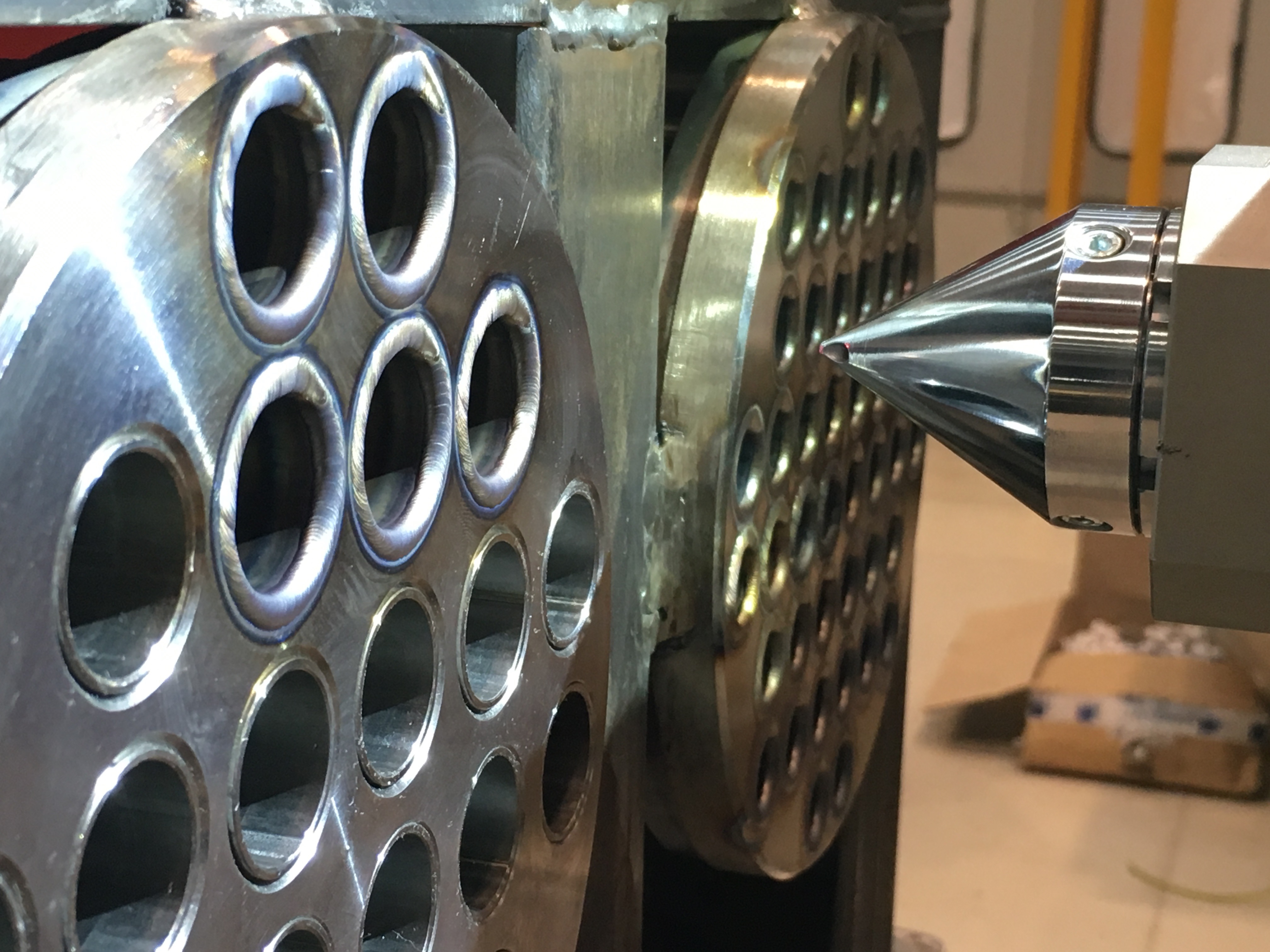

Image gallery of MaTig-502

Product technical datasheet

If you would like all the technical information related to this product, please download the .pdf brochureor get in contact with us directly, our qualified personnel will answer to your queries.