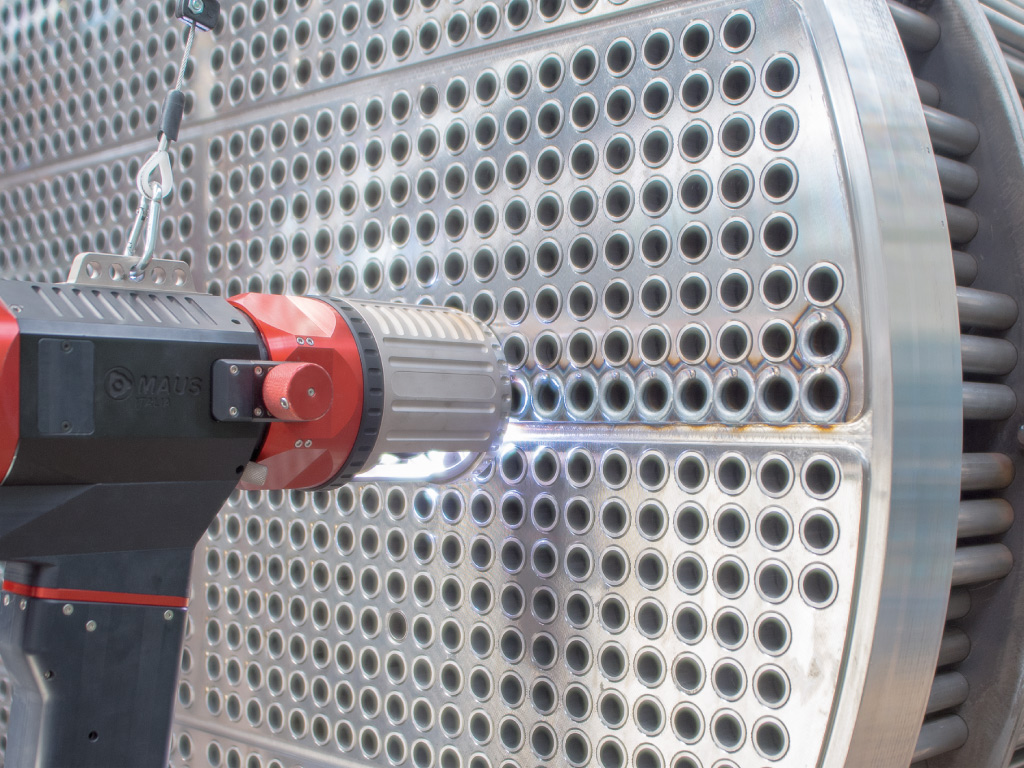

Giotto FullControl - Advanced tube to tubesheet TIG orbital welding system

Giotto FullControl - Advanced system for a total control of tube-tube-sheet TIG orbital welding

MAUS ITALIA presents the Giotto FullControl system, top-of-the-range trolley-mounted semi-automatic systems for heat exchanger tube-tube-sheet orbital welding. In-house design and construction has allowed this product to be optimised, providing a high quality system, composed by:

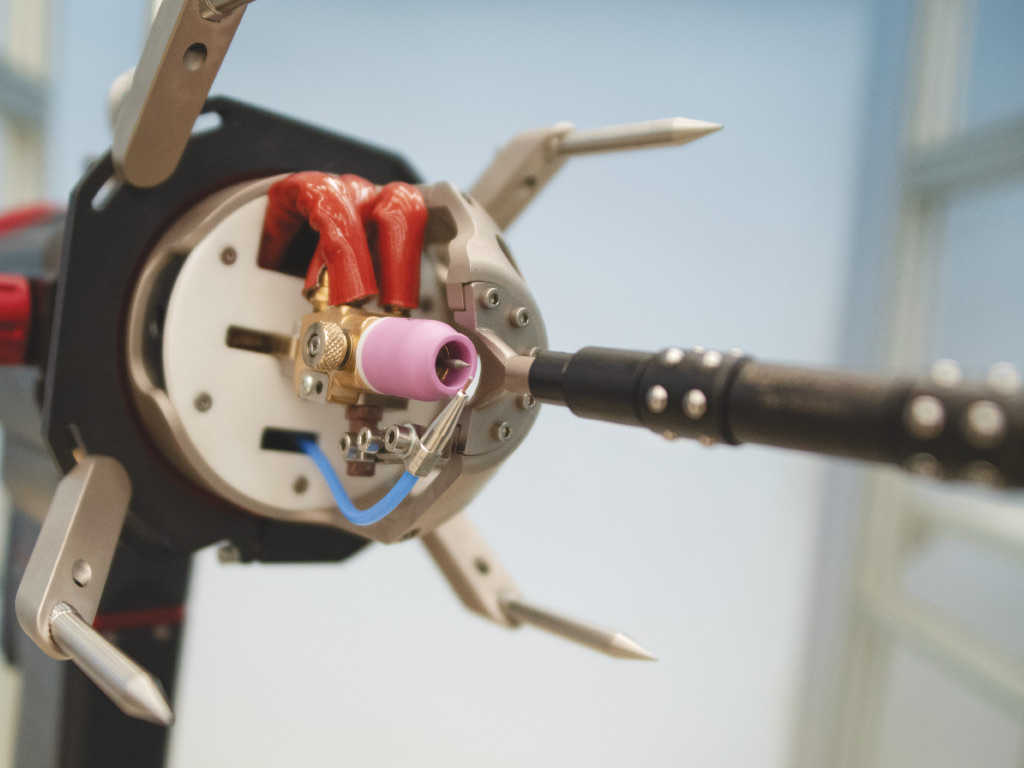

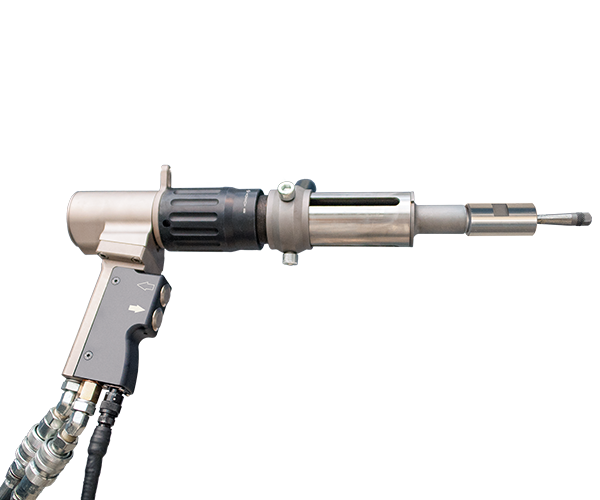

- Giotto FC 250 orbital head for tube-tube-sheet TIG welding;

- Giotto PG 300 programmer/generator with microprocessor inverter complete with cooling unit and touchscreen interface;

- Accessories, options and spare parts to meet every need for welding tubes to the tube-sheet.

Exclusive features

Pratic and ergonomic

Absolutely reliable

Extremely precise

Revolutionary features

Giotto FullControl system general features

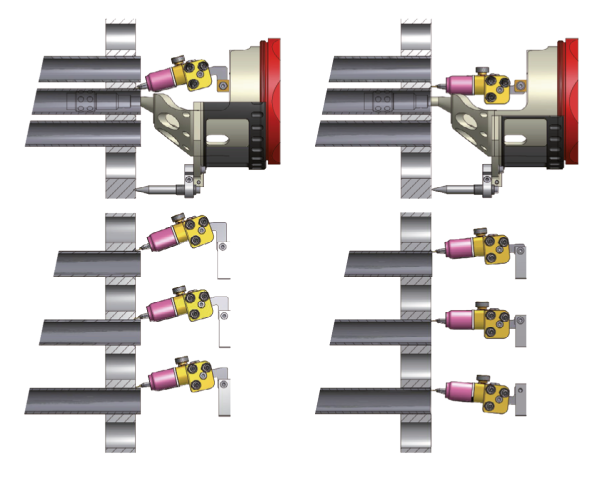

Electrode angle setup

The electrode holder system with preset angles adapts to any welding geometry and makes setup easy and repeatable.

Adjustments with a single key

All available adjustments for different welding geometries require a single supplied key.

Continuous recording of the weld

All work parameters can be stored on a USB pen drive and printed on board the machine.

Remote control with display

Simple and intuitive interface for control of welding parameters. Comes complete with all manual controls for the welding head.

Sectors

The division into up to 9 sectors of the welding cycle allows compensation for the negative effects of gravity on the welding puddle.

24/7 Usage

The enhanced cooling system inside the head allows intensive use of the system.

Test gas

The operator has the option to check and adjust the flow of the gas to the flowmeter before the start of the welding cycle.

Protective gas line

There is an additional dedicated gas line, inside the body of Giotto FC 250, for the external protection of welding.

Advanced tube-tube-sheet TIG orbital welding system

Advanced portable product, suitable for complex applications. Stands out for its reliability, precision, ease of use and robustness.

New electrode tightening system

The tangential screw does not require service keys and speeds up replacement of the worn electrode without touching other parts that could change the geometric setting.

Adjustable filler wire feed unit

All adjustments are made with a single supplied key.

Electrode angle setup guaranteed

Thanks to components with predetermined angles, the proposed system for each welding geometry is absolute and repeatable.

It facilitates geometric setup operations as well as being extremely stable and robust.

Welding with the ideal temperature

The effective internal cooling system of the Giotto FC 250 orbital welding head guarantees:

Digital programmer/generator with inverter with integrated-control microprocessor and digital interface on monitor

Powerful and compact, MAUS ITALIA's offers the GiottoPG 300 programmer/generator for controlling the TIG GiottoFC250 orbital welding head to guarantee 100% repeatability. Mounted on "carriage pickUp" with gas bottle holder.

Dedicated TIG orbital welding programming and diagnostics software

The Giotto FullControl is supplied with dedicated MAUS ITALIA software for intuitive programming of all welding parameters and prompt intervention of complete diagnostics for any malfunctions.

The simulation cycle allows you to try programs stored by the operators in advance (with space available for over 200 programs).

Maus Italia machines transform you into a Smart Factory

Compliance of the Giotto FullControl system with the requirements of the "INDUSTRY 4.0" system, has been examined by an accredited Third party and considered suitable to allow interconnection between the machine and company systems.

Sliding horizontal trolley-mounted deck for welding head support using balancer

With the aim of providing customers with every accessory necessary for tube-tube-sheet TIG orbital welding, MAUS ITALIA has designed the Slide Deck sliding trolley-mounted deck, available in two sizes: Giotto Slide Deck 1800 / Giotto Slide Deck 2800.

Balanced potential power supply for the simultaneous use of two welding systems

To promote increased productivity, MAUS ITALIA suggests the simultaneous use of two or more Giotto FullControl systems with the relevant TIG Giotto FC250 orbital heads on the same tube-sheet.

Service trolley and storage for spare parts

A tidy and well-organised workspace is synonymous with e ciency and good practice. The Giotto Service Trolley allows you to organise the consumable spare parts for Giotto orbital heads and to store all the keys and service accessories.

Image gallery of Giotto FullControl

Product technical datasheet

If you would like all the technical information related to this product, please download the .pdf brochureor get in contact with us directly, our qualified personnel will answer to your queries.