BundleCut Evolution - Band saw for the dismantling of tube bundle and recovery of heat exchanger tubesheets

BundleCut Evolution - Band saw for the dismantling of tube bundle and recovery of heat exchanger tubesheets

For when it becomes impossible t o partially retubing the tube bundle from a heat exchanger, MAUS ITALIA proposes the BundleCut band saws for the rapid, safe and ecological retrieval of the tubesheet.

BundleCut has become ”Evolution”. Years of product evolution have allowed a complete review of the design, enabling MAUS ITALIA ’s band saws to be even safer, better performing, more precise and state-of-the-art.

Exclusive features that allows rapid and clean separation of the tubesheet from the rest of the bundle

Reliable

Long-time experience

Revolutionary

New functions and features

Safety

Exclusive protections

High quality

standards

General features of NEW BundleCut Evolution system

Precise and clean cut

The tube stubs, with no deformities or metallic burrs, are removed easily without damaging the tubesheet holes.

High safety

The photoelectric barrier, if crossed, stops the blade automatically to ensure maximum safety in the cutting zone.

Ambiente sano

The elimination of harmful gases generated by traditional flame cutting and the removal of cutting dust with a grinder make the work environment healthy.

Max Tubesheet diameter

Max. tubesheet diameter 78" (2000 mm) for BundleCut Evolution 2000 version / Max. tubesheet diameter 118" (3000 mm) for BundleCut Evolution 3000 version.

Smart cutting

The ability to continuously control the speed of descent of the cutting arc allows maximum speed without compromising the life of the blade.

High productivity

Thanks to its practicality of use and the speed and precision of the cut, it is indispensable for heat exchanger maintenance workshops.

High strength

It can be used for the simultaneous cutting of the shell and the bundle as well as the cutting of solid rounds.

Rapid locking

The (optional) hydraulic press rapidly locks the tubesheet, safely speeding up the positioning operations.

User friendly

Thanks to the integrated SIEMENS LOGO! TDE panel with LED backlighting, the setting and display of parameters is quick and simple.

Blade tension control

Automatic control of blade tension and total machine stop in case the blade breaks or falls from the flywheels.

Operational simplicity

The controls on the console allow total control of the process simply, intuitively and at the correct safety distance. The ability to continuously control the speed of descent of the cutting arc allows maximum speed without compromising the life of the blade.

Digital components allows the control of:

Blade rigidity control

The blade guides, operator-adjustable using a hydraulic device, always remain alongside the tube bundle during cutting, ensuring the correct and continuing rigidity of the blade without requiring the machine to be stopped.

Compact transmission

The use of transmission chains on the movement of the lifting cyclinders reduces the overall dimensions of the BundleCut and the vertical stroke of the pistons, giving greater stability during a continuous and extremely clean cut

High rigidity in the sliding system

Thanks to pairs of profiled recirculating ball linear guides with high load capacity, the vertical movement of the arc is extremely fluid and rigid. The integrated greasing system extends times between maintenance.

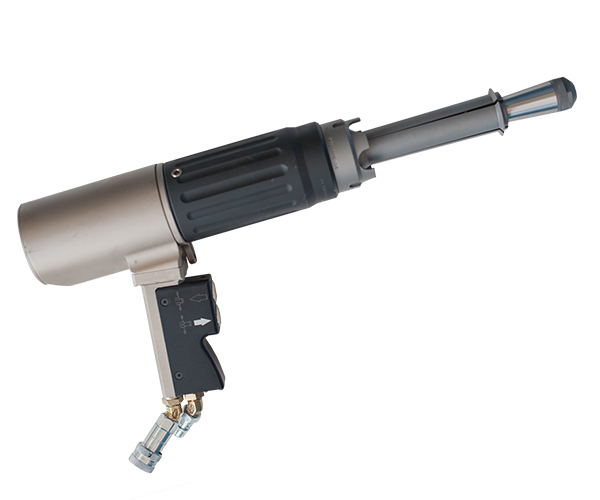

Optionals - BundlePress

In place of anchoring straps with ratcheting tensioner, MAUS ITALIA proposes a device for the rapid locking of the tube plate. It comprises a vertical hydraulic press, controlled from the console, which, mounted on the base, enables the loading of the tube bundle and the unloading of the separated tube sheet to be accelerated.

Optionals - BundleSupport

Modular structure with a standard length of 4000 mm (13 ft) for supporting the tube bundle in front of the BundleCut with sliding wedges for adaptation to the diameter of the bundle to be cut. Customisable dimensions for shapes and lengths as needed.

Cutting procedure

Image gallery of BundleCut Evolution

Product technical datasheet

If you would like all the technical information related to this product, please download the .pdf brochureor get in contact with us directly, our qualified personnel will answer to your queries.