MA-3501 - CNC single-axis or double-axis work centre with mobile base for rolling, facing, grooving and TIG orbital welding of tube bundles

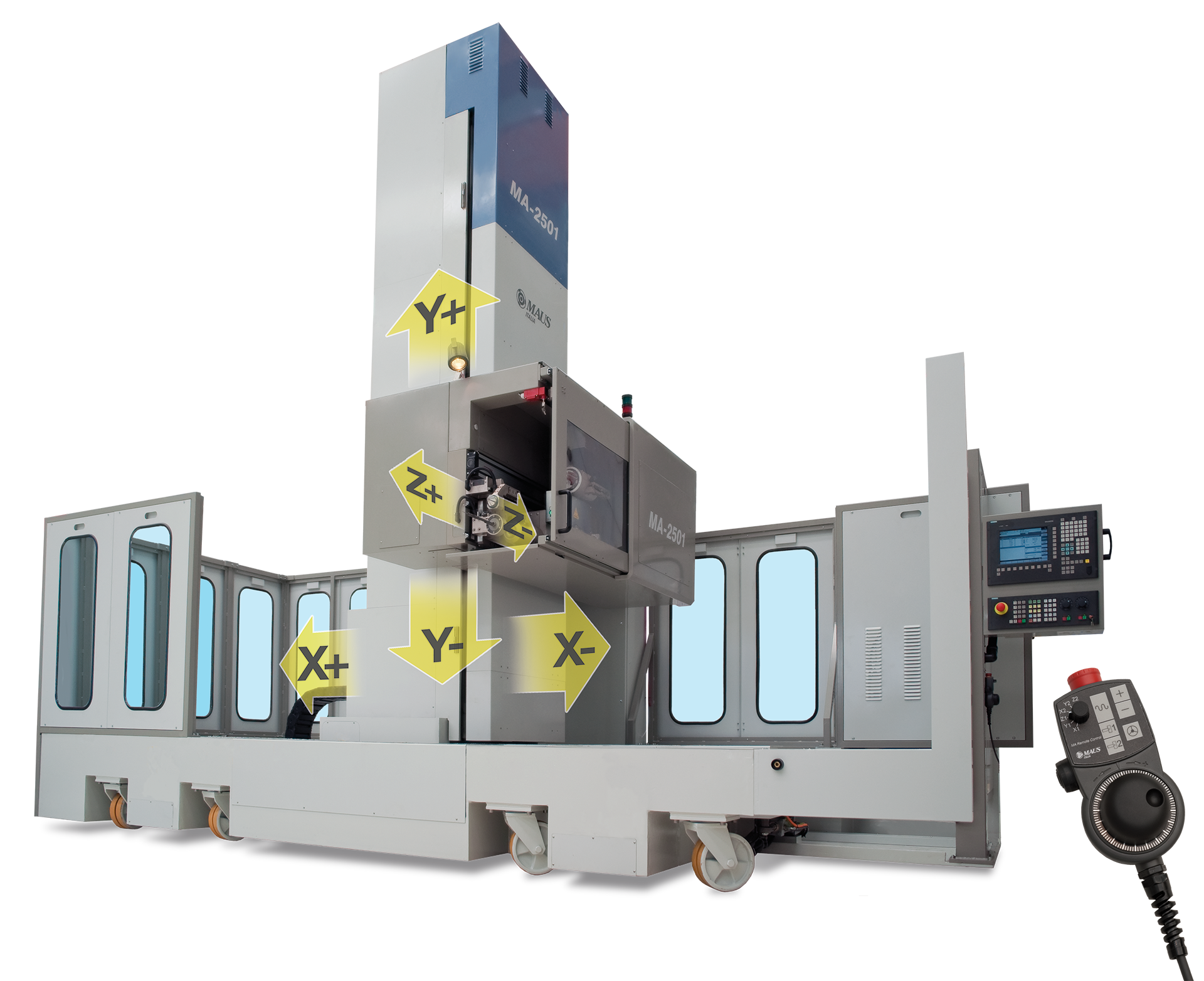

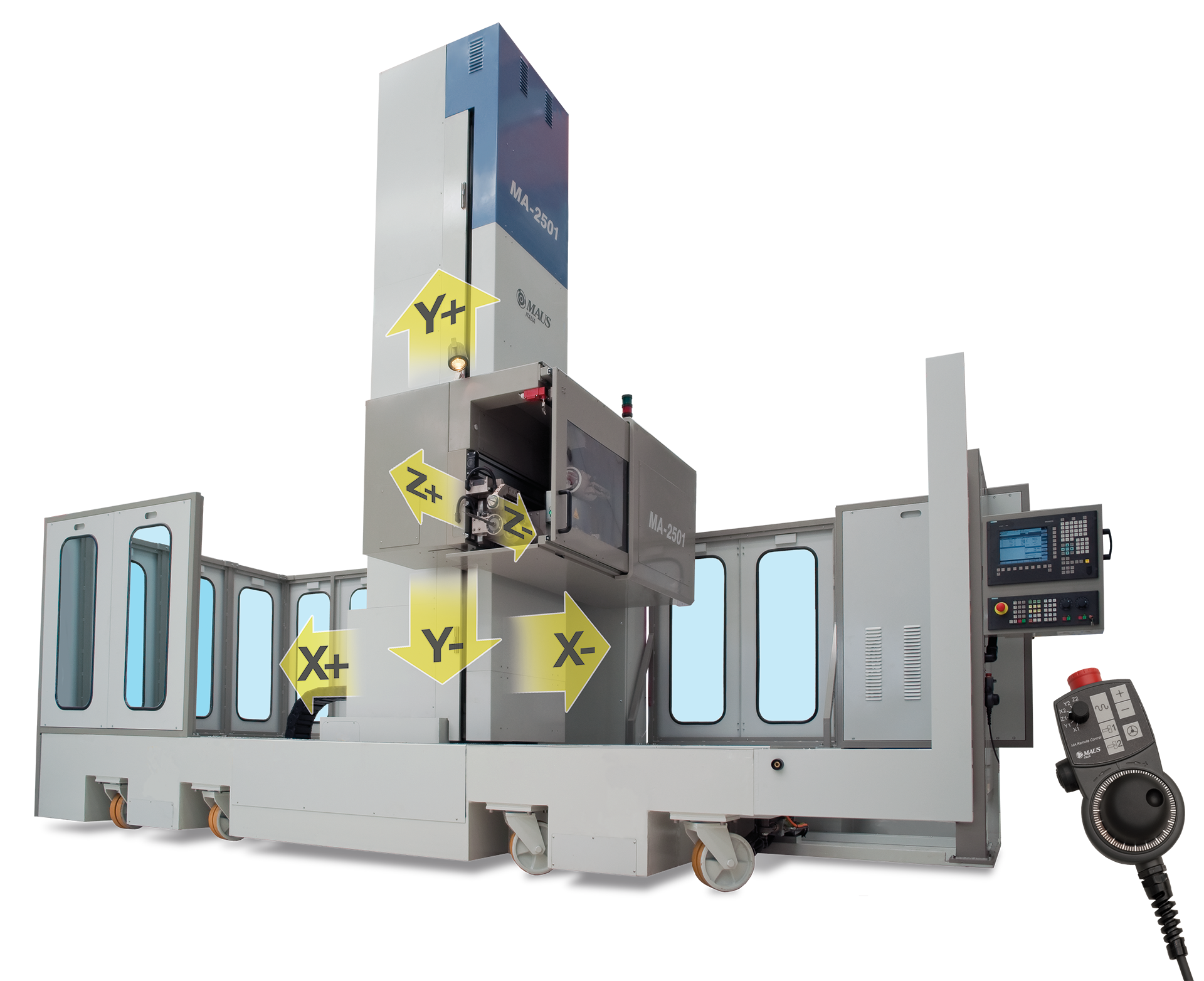

MA-3501 CNC single- or double-axis work centre with mobile base for rolling, facing, grooving and TIG orbital welding of tube bundles

The MA-3501 is the most innovative and effective solution offered by Maus Italia for the automation of work cycles for the serial assembly of medium to large heat exchangers.

The revolution is in the automation

Hi-tech

Maximum productivity

Maximum manoeuvrability

Lasting reliability

Enter the Industry 4.0 with MA-3501

The CNC/PLC machine manufactured by Maus Italia perfectly follows the requirement of the "Internet of things" being equipped of systems that allows to obtain data and statistics indispensable for handling the internal process and to be able to take strategic decision for the company development. Contact us, we will be at your complete disposal for any information.Discover the new software that can transport your company in the Industry 4.0"

CNC-controlled automatic machining

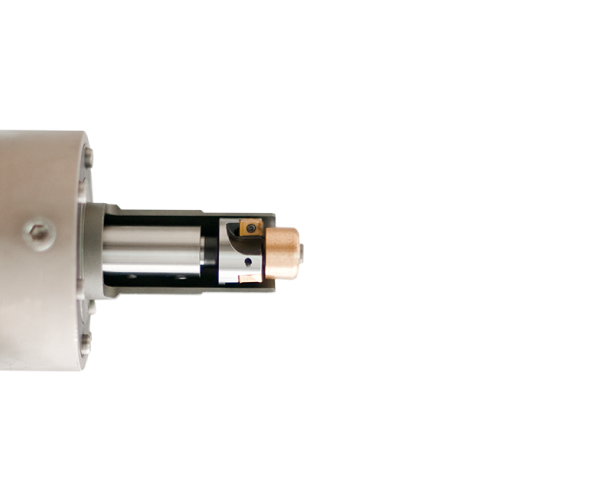

Automatic rolling expansion

The automated rolling cycle reaches levels of productivity and quality that are incomparable with those attained by traditional systems. Total control over both the torque and the size of the tube allows you to highlight and configure the phases of the process during rolling expansions, thus optimizing work times. A second advantage of this revolutionary technology is the considerable reduction in the tool wear. Complete and detailed reports and storage of data in real time.

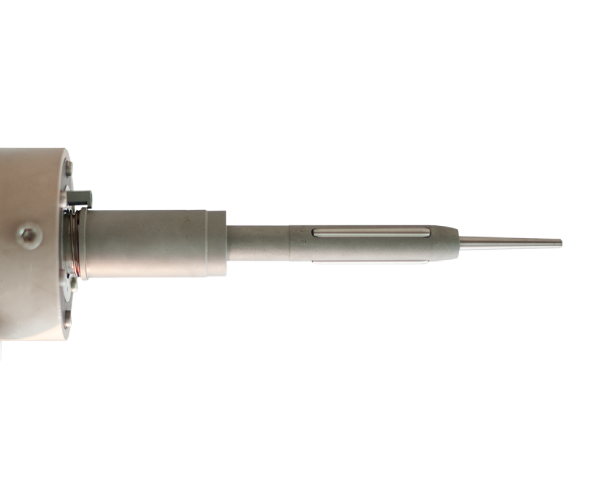

Automatic end facing

This completely automatic system can be used for removal of excess material as well as welding preparation. The automatic end facing system includes compensation for the deformation of the tube sheet, optimizing the process from both a qualitative and a productive point of view.

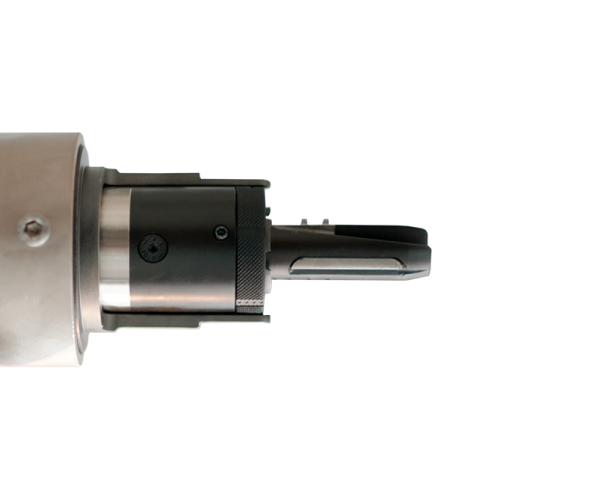

Automatic grooving( optional )

The completely automatic system can be used for creating grooves inside the tube sheet holes. The automatic cycle, complete with management and control program for the level of wear of the tools, is already programmed and only needs input of the feed speed parameters.

Automatic welding( optional )

This operation is fully automatic so as to ensure complete control of the quality and geometry of the weld puddle. Automated centering and positioning, welding and arc quenching are completely controlled by the CNC. Maus Italia has also supplemented its CNC systems with the AVC system for the automated management of the electrode/work piece distance, ensuring an even more expert performance.

The numbers that count:

The diameter of the tube sheet shown refers to a single placement; operations on greater diameters are possible with smooth and speedy multiple positioning.

The MA-3501 CNC work centre allows the single TIG orbital welding and the single or double-axis performance of rolling expansions, facing of tube bundle tubes and the grooving of tube sheet holes of medium to large diameter. Completely automated processes at extremely low cost and with a significant reduction in production times. The MA-3501 work centre is the most technologically advanced product on the market for the automation of work cycles in the assembly of tube bundle heat exchangers.

Work configurations

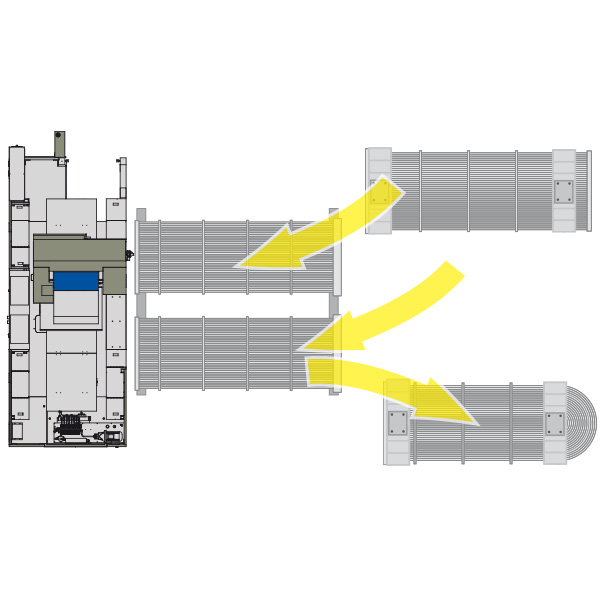

The automation of the processes in the assembly of heat exchangers permits different configurations according to the workshop, significantly increasing productivity.

Fixed location automatic operation

Fixed location configuration in which medium sized tube bundles are moved by transporting them in front of the machine, entrusting only the precision positioning to the latter.

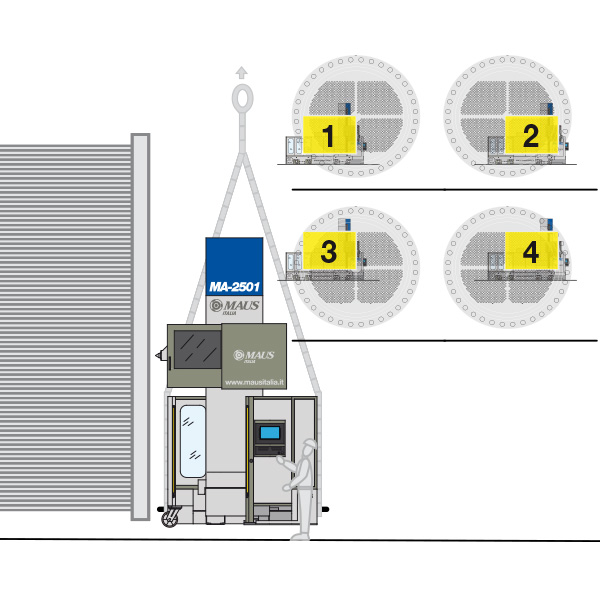

Multiple-positioning automatic operation with movement of the machine

Multiple-positioning configuration for the machining for large heat exchangers: in this case, the bridge crane brings the MA-3501 in front of the tube sheet for placement. Smooth and speedy successive positioning allows machining of the entire tube sheet to be completed.

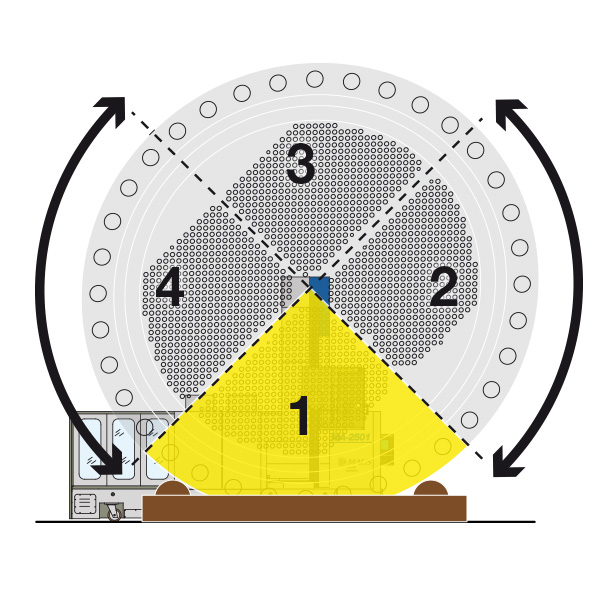

Multiple-positioning automatic operation with rotation of the tube sheet

In this case, the bridge crane brings the MA-3501 in front of the tube sheet; positioning is achieved by the rotation of the tube sheet on rollers and operations are organized by sector.

Revolutionary operation on 3 axes

The remarkable uniqueness of the MA-3501 is in its capacity to work simultaneously on 3 axes: horizontal, vertical and transverse.

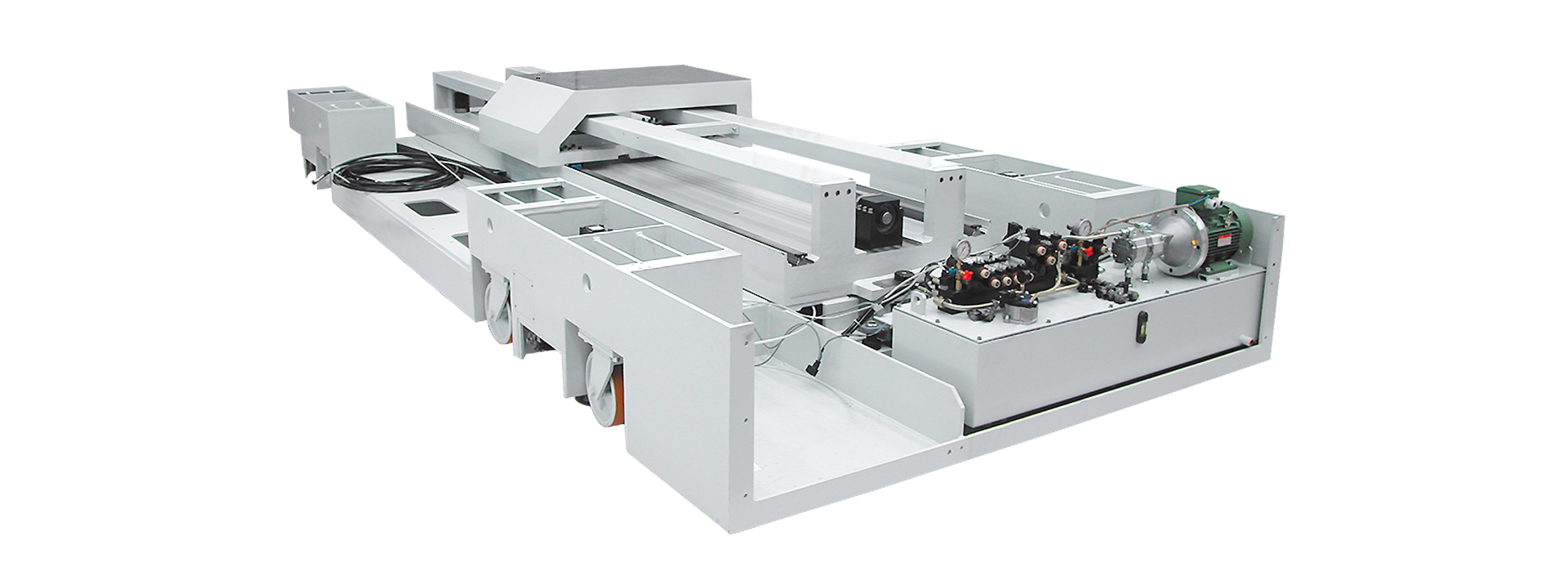

The hydraulic power-assisted base

The proper alignment of the machine with the tube sheet is fundamental for the quality of the finished piece. Thanks to the hydraulic power-assisted base, which is optional on the MA-3501, the concept of the work piece zero, typical of traditional machine tools, is revolutionized by bringing the machine to align with the work piece. With the power-assisted hydraulic systems installed on the machine, it is possible, in minutes, to move the machine along the three dimensions and, in tandem with the FOCS3 feeler, perform a correct alignment of the tube sheet zero with the CNC program. Furthermore, flexibility is complete: if the dimensions of the tube sheet exceed the useable stroke of the machine, it is possible to divide the CNC program into parts or quadrants which are not necessarily equal and proceed to the rotation of the heat exchanger or positioning of the machine into the various work sectors, an operation which is facilitated by the 8 supplied wheels.

4FD Four Feet Drive system

The power-assisted hydraulic base of the new model MA-3501 provides rigidity and precision. In particular, the 4 positioning and lifting feet help to compensate for horizontal thrusts. The transmission system sent back to each foot, guarantees, during translation, continuity and precision.

The main structure of the MA-3501

The second rolling axis ( optional )

The second rolling axis allows you to considerably increase productivity. The system allows the simultaneous processing of two tubes or tube sheet holes completely autonomously and independently of one another. The second axis encompasses the objective of productivity and quality. The complete independence of the two axes, provided by two-channel CNC technology, allows you to manage very simply and intuitively the simultaneous operation of the two installed tools.Thanks to CNC programming, assisted by the supplied MAUSCAM software, the MA-3501 automatically manages according to the size of the drill bit, the areas of the tube sheet that are workable with a double tool from those that are workable with a single tool. With a completely revolutionary device for moving the second axis, it is now possible to automatically compensate for the X2 and Y2 centre to centre distance.

The third welding axis ( optional )

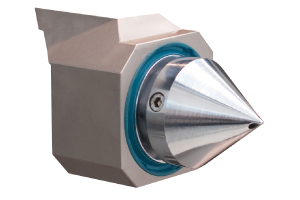

The optional third axis, for TIG orbital welding, completes the CNC work centre. With a single positioning of the machine and a sole "part program", the operator can weld the tubes to the tube sheet as well as perform rolling and milling operations. The combination of the numerically controlled positioning of the welding head with the control and correction of the FOCS3 laser feeler ensures correct centering of the welding orbit in relation to the tube which directly translates into the absolute quality and uniformity of the welded joint.

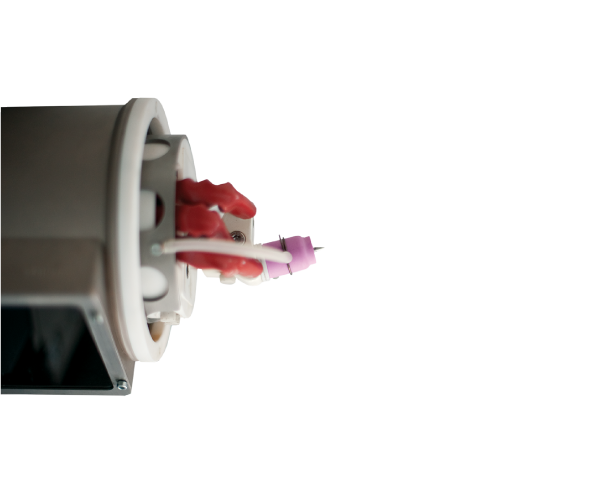

Unique FOCS3 centering system

The unique FOCS2 centering system is a self-learning electropneumatic device for automatic tubes centering and correction. This device is controlled by software exclusively designed by Maus Italia. Detection and display of the distance to the tubesheet using a class 1 laser device ( centring precision to 0,05 mm / 0,002" ). Rapid detection of work piece zero, calculation and storage of the grid location of the holes in the tube sheet. Measurement is performed by a class 1 laser system.

Applied technologies

Free tubes

The rolling of a tube which is simply inserted into the tube sheet but not locked and therefore free to move longitudinally was one of the first issues to be addressed successfully by the Maus Italia MA series. The MA-3501 can lock and roll a free tube, at the desired protrusion, totally autonomously and automatically. This technology can be used in the orbital welding preparation.

Parallel roll

RP technology allows elongations and related residual stresses in the tube after rolling to be reduced to a minimum, in order to obtain a homogeneous tube-tube sheet contact along the whole length of the expansion. This involves the use of expanders with the rolls window axis parallel to the axis of the cage: this results in a more cylindrical tube, a reduction in the elongation of the tube, the independence of the feed speed of the mandrel from the speed of rotation of the expander and a reduction in the wear of the tools.

Automatic compensation for depth of expansion

Automatic zero setting system for Z axis, the position reference is the outer edge of the tube sheet for each individual tube, regardless of the deformation of the tube sheet itself.

Mandrel feed digital control

The digital control allows you to check in real time the actual size of the tube expansion. This technology also allows you to record the value of each expansion carried out.

Continuous speed variation

The rotation speed of the expander mandrel varies continuously as a function of the torque moment by moment: this results in an optimization of the expansion cycle, a reduction in the wear of the tools and a greater speed of execution.

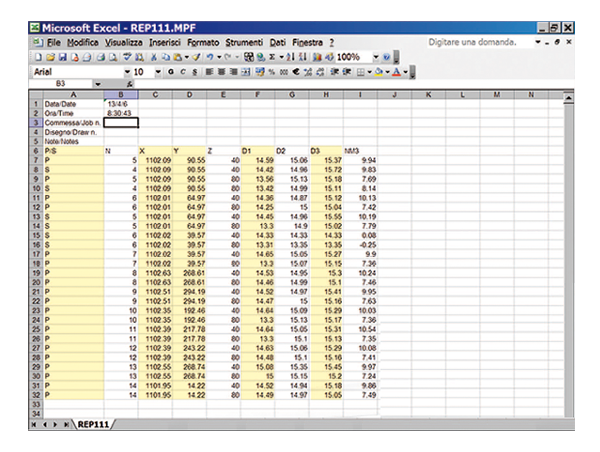

Reporting of automatic rolling expansions

The continual and growing demand for documentation suitable for certifying the overall quality of a company is met by complete and detailed data storage. The MA-3501's automatic rolling operation with torque control allows you to highlight and configure all the phases of the process which are recorded and monitored on a digital report file, guaranteeing complete traceability of each operation without the possibility of errors.

Image gallery of MA-3501

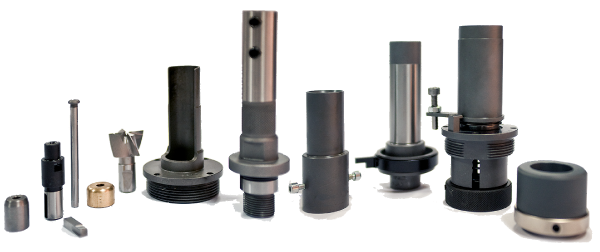

Tools and accessories for MA Series

Maus Italia offers a brief overview of tools and accessories designed and engineered for working center CNC Series MA-500, MA-2501 e MA-3501.

Product technical datasheet

If you would like all the technical information related to this product, please download the .pdf brochureor get in contact with us directly, our qualified personnel will answer to your queries.